|

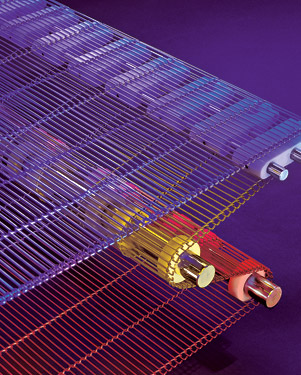

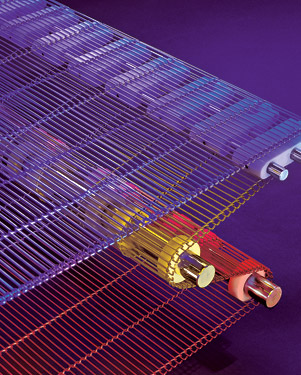

Flexx Flow Belting

Flexx Flow belting is ideal for breading, cooking, battering, coating or almost any processing application from freezing up to +500F. It has a wide range of uses in processing meat, poultry, seafood, baked goods, cereal, candy and electronic P.C. board cleaning.

Manufactured in Lancaster, PA, according to standard industry specifications, Flexx Flow belting can be spliced directly into existing belts of this type.

For help splicing, click here for video guide

Flexx Flow Features:

Since Flexx Flow belting is sprocket driven, it provides positive drive and consistent tracking. Sprockets are available in various sizes to meet your needs.

Flexx Flow belting is designed to articulate around small diameter drive and tail rolls for tight transfers. This ensures gentle handling and constant positioning of the product.

Have a belt number?

We follow industry standard belt numbers. Contact us for replacement belts!

Contact Lumsden Belting for more information or to order Flexx Flow belting.

Sizes and Specifications

42 x .062

3/8" X .062 (7.26 x 1.60mm)

42 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .063 |

41.5(+0/-.25) |

.52 |

75 |

Available in Single Loop edge or EdgeWise

Recommended For:

Seafood, meat and poultry •

Fruit, nut and vegetable processing •

Snack foods preparation •

Electronics and automotive parts manufacturing •

Textiles •

Freezing and drying processes from cryogenic to 600°F

|

24 x .072

1/2" X .072 (12.7 x 1.83mm)

24 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .072 |

.072 |

.44 |

82 |

Available in Single Loop edge or EdgeWise

Recommended For:

Commercial fryers and broilers •

Breading and battering machines •

Pizza ovens •

Tiered cooling conveyors •

Curing ovens •

Plastic thermoforming •

Textile sizing

|

24 x .092

1/2" X .092 (12.7 x 2.34mm)

24 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .0925 |

24(+0/-.25) |

.73 |

78 |

Available in Single Loop edge or EdgeWise

Recommended For:

Commercial fryers and broilers •

Breading and battering machines •

Pizza ovens •

Tiered cooling conveyors •

Curing ovens •

Plastic thermoforming •

Textile sizing

|

32 x .082

3/8" X .082 (9.6 x 2.08mm)

32 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .082 |

32(+0/-.25) |

.72 |

75 |

Available in Single Loop edge or EdgeWise

Recommended For:

Commercial fryers, broilers, ovens, toasters •

Breading and battering machines •

Bagel boilers •

Pasta cookers •

Curing ovens •

Printed circuit board reflow machines •

Dryers

|

42 x .050

3/8" X .050 (7.26 x 1.27mm)

42 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .050 |

41.5(+0/-.25) |

.33 |

80 |

Available in Single Loop edge or EdgeWise

Recommended For:

Seafood, meat and poultry •

Fruit, nut and vegetable processing •

Bakery •

Snack foods •

Electronics processing •

Silk screen printing

|

48 x .050

1/4" X .050 (6.35 x 1.27mm)

48 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .050 |

48(+0/-.25) |

.37 |

77.5 |

Available in Single Loop edge or EdgeWise

Recommended For:

Seafood, meat and poultry processing •

Fruit, nut and vegetable processing •

Snack foods preparation •

Electronics •

Confectionery

|

54 x .035

1/4" x .035 (5.64 x .90mm)

54 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Max. Belt load Per Sq. Ft. (lbs.) |

TMax. Tension per Joint (lbs.) |

Typical Open Area (%) |

| .0354 |

54(+0/-.5) |

.20 |

.35 |

3 |

82.5 |

Available in Single Loop edge

Recommended For:

Chocolate enrobing, bottoming •

Meat processing •

Fruits, nuts and vegetable sorting and grading •

Confectionery

|

72 x .050

1/8" x .050 (4.23 x 1.27mm)

72 strands per foot |

Wire Dia. (inches) |

Strands/Foot |

Weight Per Sq. Foot (Ave in lbs.) |

Typical Open Area (%) |

| .050 |

72 (+0/-2) |

.53 |

67.5 |

Available in Single Loop edge or EdgeWise

Recommended For:

Seafood, poultry and meat processing •

Fruit, nut and vegetable grading, washing, sorting, and waxing •

Printer circuit board cleaners •

Pasta cookers •

Cereal processing

|

34 x .062

9mm X 1.60mm

34 strands per foot - Metric |

Wire Dia. (mm/in) |

Strands/Ft. (305mm) |

Wt. Per Sq. Ft. (Ave in kg/lbs.) |

Typical Open Area (%) |

| 1.60 (.063) |

34 (+0/-1) |

2.14kg/sq. mtr (.44) |

79 |

Available in Single Loop edge or EdgeWise

Recommended For:

Seafood, meat and poultry breading, battering, and frying •

Fruit, nut, and vegetable processing •

Pizza ovens •

Snack food preparation •

Electronics and automotive parts manufacturing •

Plastic thermoforming •

Textiles •

Freezing and drying processes from cryogenic to 600°F

|

19 x .120

5/8" x .120"

42 strands per foot |

Wire Dia. (mm/in) |

Strands/Ft. (305mm) |

Wt. Per Sq. Ft. (Ave in kg/lbs.) |

Typical Open Area (%) |

| .120" |

19.2 |

.88 |

|

Why use Edgewise belting instead of the typical single loop edge?

Advantages:

- Standard or Double Edge

- Longer Edges - closes the opening to dramatically reduce belt snagging

- Bend down Edges - allows for a closed edge without restricting flexibility

- Bent in edges - Safety Feature! Keeps sharp wire burrs from protruding out the edge of the belt

- Smallest reverse bend - design allows for the smallest reverse bend available

- Easy to Splice - easy as our standard belt to splice and repair

- Economical - same price as our already low cost standard belt

|

Family Owned and Operated Since 1952

|

|